Sandblasting is used for complex shapes, easy to remove by hand, low efficiency, poor on-site environment, and uneven rust removal. The general sand blasting machine has various types of sand blasting guns. As long as it is not a particularly small box, the gun can be put in and cleaned. The supporting product of the pressure vessel-the head is sandblasted to remove the scale on the surface of the workpiece. The diameter of the quartz sand is 1.5mm~3.5mm.

One kind of processing is to use water as a carrier to drive the emery to machine parts, which is a kind of sand blasting.

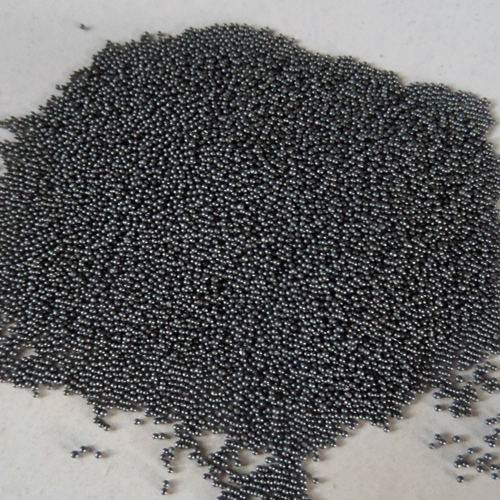

Both Shot Blasting and sand blasting can clean and decontaminate the workpiece. The purpose is to prepare for the next step, that is, to ensure the roughness requirements of the next process, and also for the consistency of the surface, the shot peening has on the workpiece. For reinforcement, sand blasting is not obvious. Generally, shot peening is a small steel ball, and sand blasting is quartz sand. According to different requirements, the number of points.

Tips and features for using shot blasting machine steel shots

Tips and features for using shot blasting machine steel shots

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?