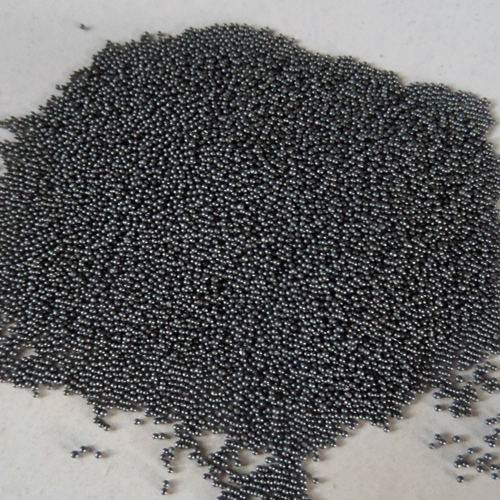

(1) Steel shot

The hardness of steel shot is generally hrc40~50. The hardness can be increased to hrc57~62 by processing hard metal. Their toughness is good, their service life is several times that of cast iron shot, and they are widely used.

(2) Cast iron shot

The hardness of cast iron shot is hrc58~65, which is very brittle, very easy to break, short service life and not widely used. It is mainly used in places requiring high shot peening strength.

(3) Glass pellet

The hardness of glass shot is lower than that of the first two kinds of shot. It is mainly used for stainless steel, titanium, aluminum, magnesium and other situations where iron pollution is not allowed. It can also be used for the second treatment after steel shot peening to remove iron pollution and reduce the surface roughness of parts.

Tips and features for using shot blasting machine steel shots

Tips and features for using shot blasting machine steel shots

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?