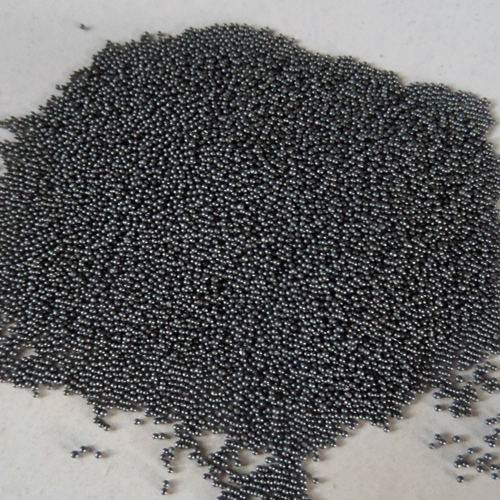

The abrasive is selected according to the hardness of the steel pipe surface, the original rust degree, the required surface roughness, the type of coating, etc. It is easier to achieve the ideal rust removal effect by using the mixed abrasive of steel grit and alloy steel shot.

Steel shot can strengthen the steel surface, while steel grit can etch the steel surface.

The mixed abrasive of steel grit and steel shot, usually the hardness of steel shot is 40~50HRC, and the hardness of steel grit is 50~60HRC, which can be used on various steel surfaces, even on steel surfaces with C-grade and D-grade corrosion. Rust works well too. The surface treatment of the steel pipe seriously affects the service life of the pipe, and it is also the simplest and most direct treatment method.

Therefore, it is necessary to strictly follow the requirements of the anti-corrosion layer specification for the surface of the steel pipe, and constantly explore, summarize and improve the surface treatment method of the steel pipe.

Tips and features for using shot blasting machine steel shots

Tips and features for using shot blasting machine steel shots

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?