Anti-rust coating process for construction machinery

The anti-rust coating process of construction machinery can generally be divided into the surface treatment process before coating and the anti-rust primer coating process.

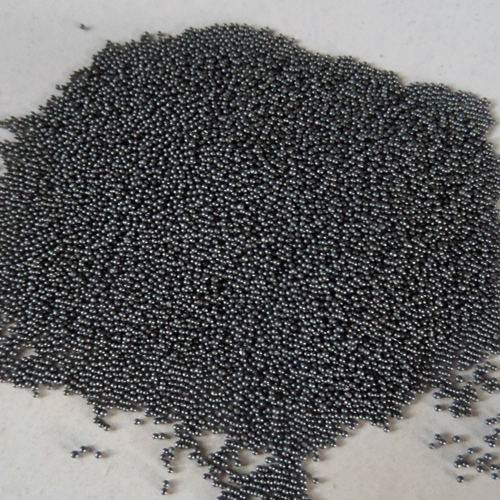

Surface treatment of steel shot and steel grit

Surface treatment is one of the important processes in anti-rust coating. The quality of anti-rust coating of construction machinery depends to a large extent on how the surface is treated.

The life of the coating is restricted by three factors: surface treatment accounts for 60%, coating construction accounts for 25%, and the quality of the coating itself accounts for 15%. According to the introduction of British Imperial Chemical Company.

The appearance of the parts is handled differently. The construction machinery industry is different.

Increase the bonding force between the anti-rust coating and the metal substrate, and mechanical cleaning can effectively remove rust, welding slag, oxide scale on the workpiece, and eliminate welding stress. Thereby greatly improving the anti-rust quality of construction machinery parts. The mechanical cleaning specification requires ISO85011:1988Sa2.5 level. The surface roughness should reach 1/3 of the thickness of the anti-rust coating, and the steel shot used for shot blasting should meet the requirements of GB6484.

The surface treatment of sheet stampings is generally called chemical surface treatment.

The process flow is:

Manual pretreatment→hot water washing→pre-degreasing→degreasing→industrial washing 1→industrial washing 2→surface adjustment→phosphating→industrial washing 3→industrial washing 4→pure water washing 1→pure water washing 2→pour water→drying or no pickling The above process can also be adjusted appropriately according to the oil and rust conditions of the sheet metal stamping parts. Or without pre-degreasing process. Degreasing and phosphating are the key processes in the chemical treatment process of steel shot, and these two processes directly affect the quality of the chemical treatment of the workpiece and the quality of the anti-rust coating. Relevant process parameters and related auxiliary equipment are also factors that cannot be ignored that affect the quality of surface treatment.

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?

What affects the wear, consumption and efficiency of steel shot?

What affects the wear, consumption and efficiency of steel shot?