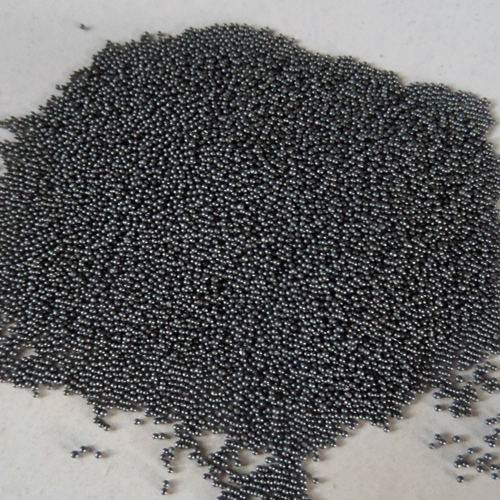

Steel shot is an industry can not be separated from a product, in the production is also two kinds of process, how is it made? The following will give you a detailed introduction, so that you can clearly understand the processing technology.

Steel shot is a kind of wear-resistant counterweight material, is the company's main production of a material, today to explain to you the production process of steel shot, so that it will be more assured in the choice.

1. Put the waste steel material after heating and quenching into the crusher for crushing, and obtain the semi-finished steel shot.

2. The semi-finished steel shot is screened and classified, that is, the finished steel shot is made. The steel shot production method of the invention reduces the process of scrap steel material melting and shot making, which must be cast into steel shot first in the traditional steel shot production process, and greatly saves the production cost.

Tips and features for using shot blasting machine steel shots

Tips and features for using shot blasting machine steel shots

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?