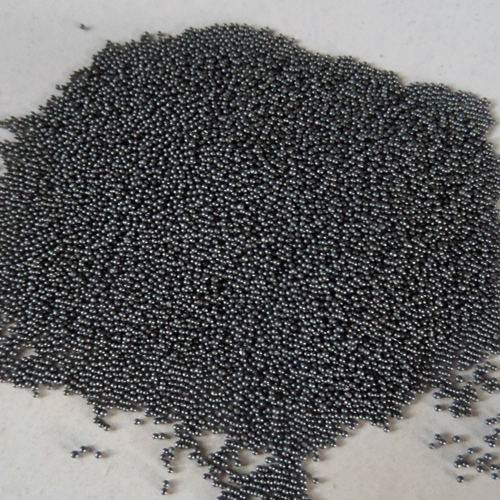

Steel shot is widely used for derusting and descaling of steel workpieces before painting, and centrifugal shot blasting equipment is often used in this case. The spherical shape and low hardness make the steel shot not seriously wear the equipment. Steel shot is also widely used in foundry industry. When the workpiece is taken out of the mold, steel shot is used to remove the sand on the surface of the workpiece.

Melting high-quality molten steel, then spraying molten steel with a high-pressure water spray gun to form steel balls, reheating and homogenizing the formed steel balls, and then quenching. The quenched steel shot is dried, reheated and tempered in the furnace to achieve a suitable hardness. The tempered steel shot is screened by the mechanical sieve of the shot blasting equipment into a grade that meets the SEA standard. Products of different grain sizes and hardness are used in different processes such as descaling and surface strengthening of steel. When adding new steel shot, please observe the principle of small amount of effort.

Steel shots are selected raw material scraps, rare metals and alloys with the best ratio. They are smelted in an electric furnace and produced by modern equipment. In the process of forming steel particles from liquid metal, the chemical composition and particle size are strictly controlled to ensure that its mechanical properties meet various purposes. Every production link has the strictest quality management. The produced steel balls have compact structure, not easy to break, uniform particle size distribution, suitable hardness, strong impact resistance and long service life.

According to the work requirements of the automobile manufacturer, some castings of the steel plates used need to be polished, but the strength and original appearance of the steel plates must not be damaged, and the appearance of the castings should be clean and beautiful. Because car parts are not very regular, they need to be polished with different polishing machines. The required shot blasting machines are: drum, turntable, crawler, through-type shot blasting machine, different machines handle different workpieces.

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?

What affects the wear, consumption and efficiency of steel shot?

What affects the wear, consumption and efficiency of steel shot?