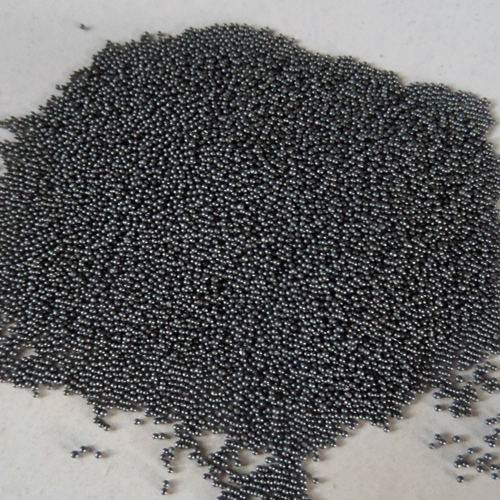

High-carbon steel shot is also called: high-strength reinforced steel shot, reinforced steel shot, spring steel shot.

Production process: It is refined by wire drawing, cutting, strengthening and other processes, and is produced in strict accordance with German VDFI 8001/2009 and American SAE J441, AMS2431 standards. The particle size of this product is uniform, and the hardness of the product is HV400-500, HV500-555, HV555-605, HV610-670 and HV670-740; the particle size of the product is from 0.2mm-3.0mm; the shape is round cut shot and round shot Degrees G1, G2, G3; service life from 3500 to 9600 cycles.

Features:

1. Reinforced steel shot has stronger toughness and is not easy to break, so it has long service life and strong impact resistance. It can reach the strength of spray (shot) shot in a faster and shorter time, and can maintain the strength of spray (shot) shot for a longer period of time. ;Lower consumption during use;

Our company's strengthened grinding shot has made a lot of improvements on the basis of traditional strengthened steel wire cut shot;

○a Using high-quality alloy steel wire as the base material, the performance is higher and more stable;

○b Improved the wire drawing process to make its internal organization denser;

○c Improved the traditional grinding process that relies entirely on throwing, reducing the damage of the shot itself during the throwing process, and further improving the service life;

2. When selecting better shot peening equipment, reasonable shot peening process, and selecting reinforced steel shot, it can obtain cyclic strain hardening microstructure structure in the surface layer of the workpiece and introduce an optimized residual compressive stress field into the surface layer. , the outer surface can obtain low surface roughness, thereby increasing the fatigue life of the processed workpiece by 30%;

3. Strengthened steel shot can bring higher shot blasting cleaning quality and significantly improve cleaning efficiency. Taking conventional spring cleaning and gear cleaning as examples, compared with ordinary high-carbon steel shot, the cleaning efficiency of reinforced steel shot is higher. Can be increased by more than 50%;

4. The higher service life of reinforced steel shot will greatly reduce the dust generated. Compared with ordinary high steel shot, the dust emission will be reduced by at least 30%, which reduces the compliance of the dust removal system and prolongs the service life of the dust collector. , while reducing the pollution to the environment, it is a real green steel shot.

Product parameters:

Specifications: 0.2mm-3.0mm, can be customized according to customer needs.

use:

1. Aviation strengthening: aviation blades, axles, landing gear, etc.

2. Strengthening of locomotive and automobile industries: train hubs, stabilizer bars, springs, crankshafts, gears, leaf springs, etc.

3. Oil exploitation: machine shaft, oil sucker rod, mine drill, etc.

4. Ship strengthening: chain anchors, chain bolts, valves, engine connecting rods, etc.

5. National defense and military industry: firing pins, camshafts, compressor blades, etc.

6. Machine tool strengthening: milling cutter, punching tool, etc.

7. Building reinforcement: Subway high-strength guardrails and other packaging:

Package:

Inner packing: 25kg/bag inner film bag.

Outer packing: nylon woven bag, kraft paper bag, carton.

Whole ton packaging: pallet or ton bag.

Tips and features for using shot blasting machine steel shots

Tips and features for using shot blasting machine steel shots

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?