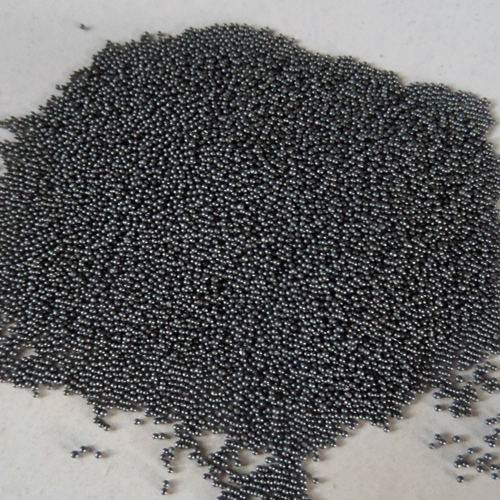

In the process of using grinding and strengthening steel shot, the product is consumed little by little, and it will be gradually worn out during this use process. Once its service life is over, it may no longer meet the requirements of use. In this case, we need to replace the product and place a new one for reuse. If the product is severely worn during this process, but there is no time to replace it, it is likely to seriously affect the entire work. So, how to deal with the product after use?

1. If the Shandong steel shot is dumped directly as waste after use, a lot of resources will be wasted.

2. In fact, the value of alloy steel shot after use is quite high, and it can be used after secondary treatment.

3. For example, after the abrasive and strengthened steel shot is used as sandblasting and polishing, it can be sold back to the manufacturer. After the manufacturer selects and crushes it, there can be sand with small particle size, and it can also be used as a counterweight material to be sold to machinery counterweight enterprises.

4. The mortar mixture can be used as raw material and sold to chemical companies in the future. From the above introduction, it is not difficult to see that the ground and strengthened steel shot can actually be used repeatedly. Many manufacturers think that the product has been damaged and has no use value, so they throw it away as waste, which causes a lot of waste of resources, so proper recycling can reduce our cost to a certain extent economy. It should be noted that because the product is recycled, it is slightly polluted and mixed with impurities, which will affect the use effect. At this time, it is necessary to perform self-cleaning operation.

Tips and features for using shot blasting machine steel shots

Tips and features for using shot blasting machine steel shots

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?