We all know that

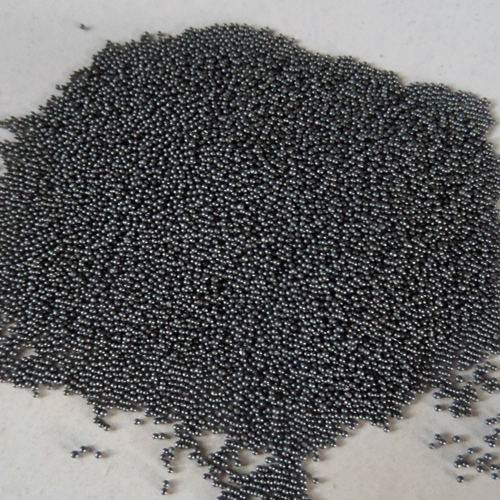

steel shot is the main consumable of the workpiece in the process of shot blasting. The wear of good high-quality steel shot is a slow process. The steel shot hits the surface of the workpiece after being accelerated by the shot blaster, without a single impact , the steel shot deforms once, and a layer of metal will fall off. The shape of the steel shot is similar to a football, which is a polygon. The impact effect of each direction on the casting is also equal. After many times of impact, the steel shot keeps getting smaller. , when it is small to a certain extent, it will be sucked away by the dust collector, or separated by the shot sand separation device. The shot blasting separator is the brain of the shot blasting machine. This metaphor shows its importance in the whole set of shot blasting equipment. During the working process of the shot blasting machine, the performance of the shot blasting separator will directly affect the cleaning efficiency. and cleanup costs. The work of shot sand separation is to separate the impurity sand knocked off from the casting and the steel shots that have been ground to a small size or have been crushed from the steel shots in normal use, so as to ensure the cleaning efficiency and reduce the wear on the shot blasting machine. When the shot blasting machine is working, sand is the main cause of equipment wear. According to statistics, every 2% increase in sand will reduce the life of wearing parts by half.

The roughness of the casting surface after shot blasting is closely related to the strength and projecting speed of the steel shot used. The larger the particle size of the steel shot, the higher the roughness of the workpiece surface, the faster the projecting speed of the steel shot, and the surface of the workpiece The higher the roughness, the lower the surface roughness obtained by mixing steel shots with multiple particle sizes than single-size steel shots.

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?