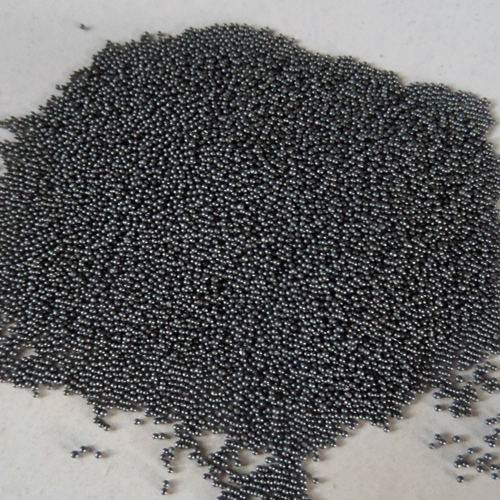

1. The defects of the steel shot itself are not produced according to the normal production process, which shortens its service life; the hardness is unreasonable, hollow, and the special shape exceeds the national standard, which ultimately reflects the large consumption of steel shot.

2. Reasonable jetting speed, normal cleaning speed is 65-78 m/s, workpiece strengthening speed is 91-95 m/s; whether the load value of the ammeter is within the operating range; the projection angle when the shot blasting machine is installed, etc.

3. Whether to choose a steel shot with a reasonable hardness for cleaning according to the hardness of the workpiece is also affected by factors such as the degree of sand sticking of the casting and the degree of rust of the steel.

4. On-site equipment has not been overhauled for a long time, staff operation, etc.

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?

What affects the wear, consumption and efficiency of steel shot?

What affects the wear, consumption and efficiency of steel shot?