The influence of abrasive impurity content on abrasive quality is comprehensive, that is, it affects the grinding effect and grinding efficiency, and even affects the performance of the object being ground.

Although the inherent properties of abrasives, such as hardness, chemical composition, chemical stability, etc., also affect the performance, they are determined by the raw materials, not by the micropowder process, so they will not be discussed here.

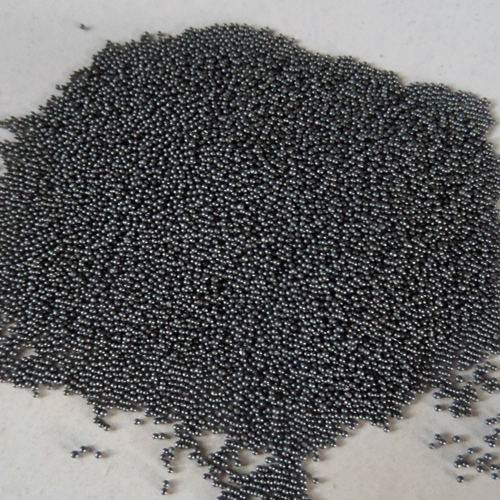

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?