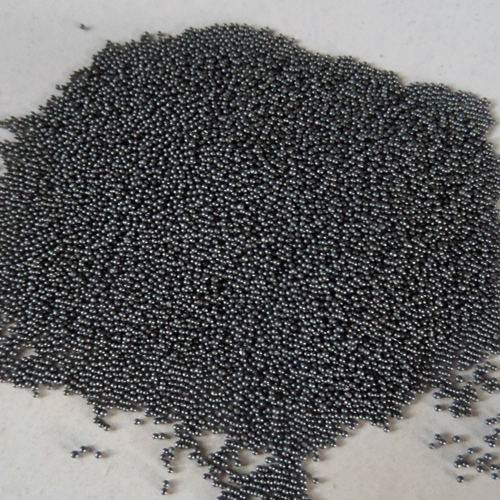

Shot blasting is to use the high-speed rotating impeller to throw small steel shot or small iron shot at high speed to hit the surface of the part, so as to remove the oxide layer on the surface of the part. At the same time, the steel shot or iron shot hits the surface of the part at high speed, causing the lattice distortion and deformation of the surface of the part, thereby increasing the surface hardness. This is a method of cleaning the surface of the part. Shot blasting sand is usually used to clean the surface of castings or to strengthen the surface treatment of parts.

Shot blasting is a finishing process that acts on metal surfaces, similar to sandblasting and shot blasting. By throwing spherical projectile particles onto the surface of the metal workpiece, the surface roughness of the workpiece is changed by a strong impact force, and the adhesion of the paint film of the subsequent coating of the workpiece is also improved, thereby improving the mechanical properties of the workpiece. Shot blasting sand is almost used in most mechanical fields, such as shipbuilding, auto parts, aircraft parts, artillery and tank surfaces, bridges, steel structures, glass, steel plate profiles, anti-corrosion of inner and outer walls of pipelines, and even road surfaces.

The characteristics of shot blasting sand

1. High cleaning efficiency, low cost, fewer operators, easy mechanization, suitable for mass production.

2. There is no need for compressed air to accelerate the projectile, so there is no need to set up a powerful air compressor station, and the surface to be cleaned is also free of moisture.

3. Poor flexibility, limited by the site, some blindness when cleaning the workpiece, easy to produce dead corners that cannot be cleaned on the surface of the workpiece.

Previous: Brief introduction of abrasive pellets

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?

How many steps are there in total to inspect the anti-corrosion coating construction of steel structures?