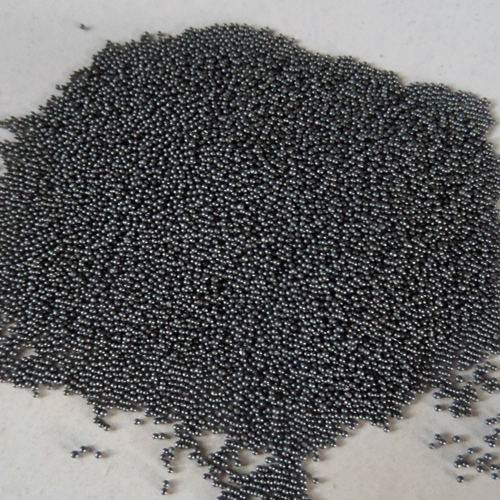

The production of stainless steel shot is refined by drawing, cutting, strengthening and other processes. The particle size of this product is uniform

Stainless steel shot is a kind of spherical particles made of special materials through special heat treatment. First, high-quality steel blocks are melted, and then the molten steel is sprayed with high-pressure water to form particles, and the formed shot body is reheated again to purify the uniform quality, and then quenched. The quenched shot body is dried and reheated and tempered in the furnace to achieve the applicable hardness. After tempering, the steel shot is sorted into different grades of products through mechanical screens for different shot peening equipment. A good steel shot product can apply more kinetic energy to the surface of the workpiece, effectively cleaning and strengthening, has a long fatigue life, effectively reduces the loss of steel shot during work, and reduces costs. The hardness of steel shot. If the steel shot or steel grit is too soft, it will slow down the cleaning speed and reduce the working efficiency. During shot peening, steel shot that is too soft cannot produce suitable residual stress, and the force of low hardness shot cannot be compensated by increasing the impact time. If the hardness is too high, it will produce an unsatisfactory surface shape, increase the chance of breaking the projectile, make the consumption too high, and cause greater wear and tear on the equipment, increasing the maintenance cost of the equipment. Therefore, appropriate hardness is also critical.

Tips and features for using shot blasting machine steel shots

Tips and features for using shot blasting machine steel shots

Applications of low carbon steel shot

Applications of low carbon steel shot

The influence of steel shot quality on cleaning effect

The influence of steel shot quality on cleaning effect

What is the ratio between steel shot hardness and service life?

What is the ratio between steel shot hardness and service life?